As humanity explores beyond our Earth we will need new systems to adapt to our life in space. We envisage colonies on the Moon and Mars and will need to plan new structures and what such buildings may look like. We may wish to easily transform satellites to respond to changes and build new structures in space that can easily adapt on command.

Spaceoneers spoke with Pavlina Vardoulaki, who together with her team at the Design Research Laboratory at the Architectural Association School of Architecturein London developed a self-assembly system that allows cubes to be reconstructed on demand. These “Hypercells” are dynamic and can respond to changes in their environment. Every cell can make its own decisions and has the ability to climb, roll and change its shape. A number of cells can come together without pre-defined instructions to form larger structures.

How did you come up with the idea of the Hypercell?

Hypercell is a self-assembly system developed at the Architectural Association Design Research Laboratory, founded by Patrick Schumacher and directed by Theodore Spyropoulos. Hypercell is part of the Theodore Spyropoulos Studio and was developed as a team project by Pavlina Vardoulaki, Ahmed Shokir, Coskus Cinkilik and Houzhe Xu. Architecture today is usually developed as static objects, while the world is very dynamic. We were interested in developing a system that can respond to changes through self-awareness, mobility, softness and re-configurability. A time based system that has no final form, but rather in continuous formation.

How long would it take to form an architectural structure with Hypercell? How does this compare with conventional urban planning?

Urban planning developments cannot be accurately predictable in present volatile dynamic society. The city of the future will be able to accurately predict the change it needs and respond without top down command. Our system is an ecology of constant change and re-configurability. We developed mechanisms to address these changes. Based on local decision making our system exhibits mobility, aggregation and structure generation. Through local interaction, they are able to create a multitude of spaces. We studied mass populations and their behaviour – how as an ecology they are able to collectively create structures. A meaningful architectural structure can be assembled in about an hour with around 4,000 cells.

What information is required to form such a structure? Can they accept remote commands (c.f. telecommunication)?

A number of cells are able to come together without predefined instructions to create meaningful structures. Computational and physical strategies of self-assembly were developed which demonstrate the ability of the single cell and the collective. These strategies show aggregations created with goal oriented strategies. Through local decision making, the system will consciously create space from local and global data. HyperCell can respond to city driven events and create the required space through the collection of the city’s existing data, forecasted data, live data, and studies from research groups and valuable statistics. Therefore, a specific design outcome or appearance is not required as input. The relevant input which informs the cells how to act are the goals they need to achieve.

What materials are the Hypercells made of?

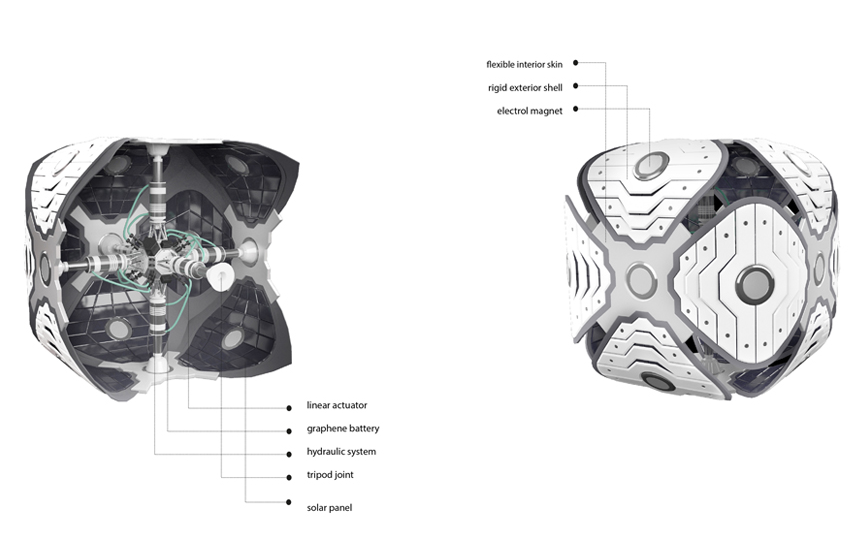

Every individual cell can take its own decisions and can perform in terms of mobility, energy collection, transforming and climbing. A 3D printing technique using flexible PLA skin with rigid parts was introduced to the fabrication to make the cells robust and simultaneously flexible. The cell was fabricated from a single flat sheet and by connecting the edges we create its final form. We explored the behaviour of a number of models created with different patterns. These patterns gave various flexibility to the component, which in turn resonates onto its mobility and ability to self-structure. This portion of the research was concluded with the most flexible and simultaneously mobile cell. The flexibility of the shape can enable the movement of one cell on top of another one. The shape gives it the ability to roll and simultaneously it can compress and store energy to pop back in its initial shape. This is the first and basic action upon which we developed our strategies of self-assembly.

How durable are they? Can they withstand intense vibrations and changes of temperature (namely the harsh conditions of space)?

Hypercell has not been specifically tested for vibration and temperature. We are convinced that the cells will stand up fairly well to vibration considering they are comprised of robust parts which are meant to move. The cells are always moving, changing shape, rolling, climbing, and stacking. In terms of dealing with movements, they hold up fine, but they should be further tested against intense vibrations to ensure fastening systems stay in place. Hypercell has yet to be introduced to any harsh temperatures. The internal components should hold up to an extent, but the movement system should consider the possibility of expansion / contraction of moving parts under extreme heat or cold. The biggest concern would be the skin. Hyper cell’s skin is a flexible plastic which is needed to allow the cells to shape shift from a sphere to a box. This skin would need to be tested for the cold conditions of space to make sure the material would not become too stiff to move, resulting in the skin cracking.

How much have they been tested under different environmental conditions?

The cells have not been tested greatly in terms of various environmental conditions. The current stage of development was focuses solely on getting the system to work in a base control environment. The next stages should be of testing in various conditions to improve the design. We have the idea that cells can be specifically tailored for desired uses. For instance, cells used in a marine environment would need water proofing, but water proofing would not be needed for cells being used only indoors. Rather than create a cell that can withstand every possible condition, we believe it makes more sense to have special additions to cell durability based on specific environmental needs. This will cut redundancy in production and cut costs on cells that wouldn’t need additional features.

How much does each one weigh? Can they easily be stacked together?

The single cell is 10 cm by 10 cm and it weighs about 26 grams without the inside mechanism and since its made out of flat PLA sheets, thousands of them can be stacked together and shipped separately from the inner mechanism, which is also compact. The size can of course be shrunk or enlarged based on the specific needs for the cells by varying the internal system and calculating any additional structural needs from the new weight of the cells.

How adaptable is the structure of the Hypercell?

Moving on to a much larger population scale we started investigating the adaptable space-making logic of our system which is based on local decision making and biased by global information. In the collective scale of operation, our system shows organisation, self-structuring and space-making. The self-structuring strategy is based on the real-time self-evaluating processes and decision making logics, aiming at generating stable structures and providing architectural spaces. It is not just a one-way build-up process. A large population of cells is involved in this space-making process, each of which is aware of the local conditions including the global goals that are assigned to the system and is capable of making the optimised decision that benefit the system most while keeping the stability of the structures. Managing large numbers of cells to create space involves real time structural analysis. If the system is in energy saving mode, the space takes more time. The system is able to remove redundant cells that can migrate to other parts of the structure where more cells are needed to carry the structural loads. HyperCell is an ecology of constant change, adaptation and re-configurability.

What important design changes do you think might be needed to adapt the Hypercells for the space environment?

Every cell begins from the core – it is a single steel core with 6 linear actuators, which each can take up to a 100 kg force and 25 kg sheer force on earth. The core and the actuators are linked through nano-actuators which allow the movement of 360 degrees. A hydraulic system gives high power and at the same time, smooth continuous motion. On earth, the biggest challenge was the objects weight in terms of structure and movement. We needed a good amount of force to get the cells to role and also to allow them to travel up each other and stack. Since there are no gravitational forces in space, the biggest change would have to be in its movement rather than its structure. In space we do not have a constant ground plane for the initial movement of the cells. This means the cells may need to consider some system of creating thrust to position themselves in space. Once the cell has attached to other cells, it can use the magnets and linear actuators to travel along the structure formed by the other cells. A further study might need to be done on how these magnets would react in space as a collective, as they may try and orient themselves towards earth or the closest planet. There would need to be a test on the cells in a temperature similar to that of space as some components may react unexcitingly from the cold. Lastly, the current design uses solar energy to power the cells, this may be an issue depending on the location in space that the cells would be utilised.

—

Many thanks to Pavlina Vardoulaki for her valuable contribution towards this article.

Lead image: A number of hypercells are able to come together without predefined instructions to create meaningful structures. Credit: – Authors : Cosku Çinkiliç, Ahmed Shokir, Pavlina Vardoulaki, Houzhe Xu. University: Architectural Association Design Research Laboratory (AADRL), Studio Theodore Spyropoulos http://superarchitects.world/portfolio/hypercell/